Coating Thickness Gauge TIME2605

Featured

Featured |

Coating Thickness Gauge TIME2510

$0.00 |

|

Surface Roughness Tester TR100

$800.00 |

|

TIME Portable Hardness Tester TIME5104 (TH174)

$0.00 |

|

Ultrasonic Thickness Gauge TIME2130 (TT300)

$0.00 |

Features:

Mmagnetic induction (F) measure the thickness of non-magnetic materials(e.g. Paint, plastic, porcelain enamel, zinc, aluminum, chrome etc.) on magnetism substrate(e.g. iron, nickel etc. )

2 measurement way: continue / single

5 statistical ways: Mean values / Max. values / Min. values / testing numbers.(No.) / standard deviations (S.DeV)

10000 measured values can be stored

Integrated with printer for convinient use

Low battery indication

2 switch off modes: manual and auto

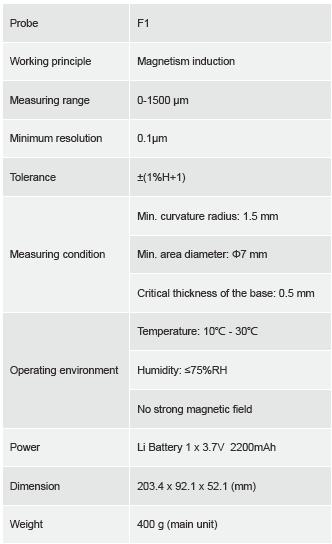

Technical Specification:

|

|

|||||

|

|||||

Optional probes and technical specification:

|

Probe model |

F400 |

F1 |

F1/90º |

F10 |

N1 |

CN02 |

|||

|

Operating principle |

Magnetic induction |

Eddy current |

|||||||

|

Measuring range (µm) |

0-400 |

0-1250 |

0-10000 |

0 to 1250 μm |

10~200 |

||||

|

Low range resolution (µm) |

0.1 |

0.1 |

10 |

0.1 |

1 |

||||

|

Accuracy |

One-point calibration (µm) |

±(3%H+1) |

±(3%H+10) |

±(3%H+1.5) |

±(3%H+1) |

||||

|

Two-point calibration (µm) |

±[(1~3)H%+0.7] |

±[(1~3)H%+1] |

±[(1~3)%H+10] |

±[(1~3)%H+1.5] |

- |

||||

|

Measuring conditions |

Min curvature of the min area (mm) |

Convex |

1 |

1.5 |

Flatten |

10 |

3 |

Flatten |

|

|

Diameter of the min area (mm) |

φ3 |

φ7 |

φ7 |

φ40 |

φ5 |

φ7 |

|||

|

Critical thickness of substrate (mm) |

0.2 |

0.5 |

0.5 |

2 |

0.3 |

unlimited |

|||

Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Categories

Categories